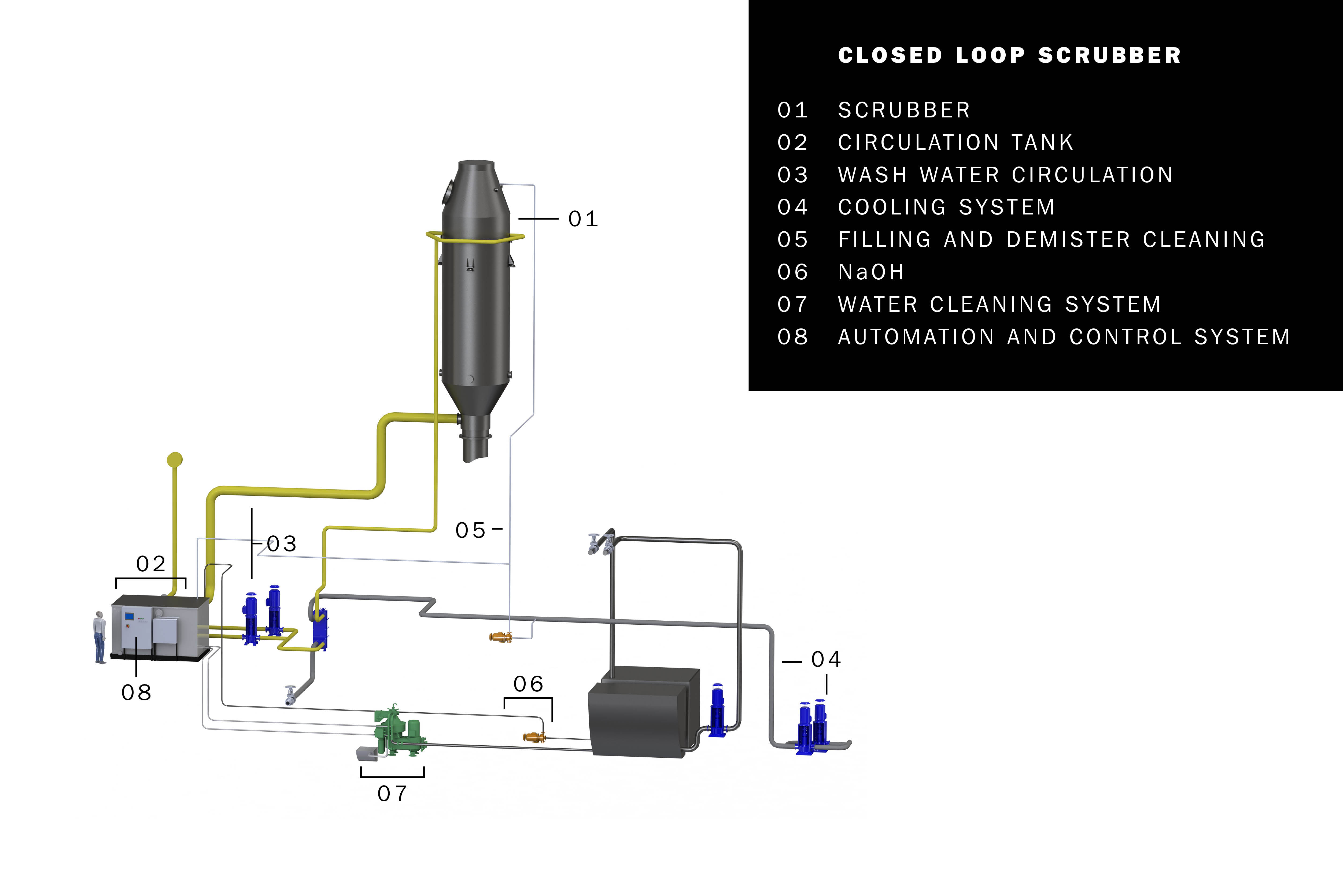

The CLOSED loop is the most frequently used system. The seawater used in the process is continuously re-circulated.

How does it work?

- • From the bottom of the scrubber exhaust gases are led through the scrubber to the top.

- • The seawater is fed into the top of the scrubber through nozzles. This results in an equally divided spray.

- • The outgoing exhaust gases are washed with seawater in the scrubber.

- • The seawater (process water) is continuously re-circulated.

- • The sulphur in the exhaust gases dissolves in the process water pumped from a circulation tank and binds with the caustic soda (NaOH) as a salt.

- • Based on conductivity level a certain amount of process water is drained out of the system automatically

- • If needed clean seawater is then added to the process water tank and also NaOH, if needed.

- • The process water is pumped through the separator.

- • This separator will separate solids and oil from the process water.

- • The remaining sludge is pumped to the sludge storage tank on the ship.

- • The process water with high conductivity level will be discharged directly back to sea while complying fully to the IMO regulations.

- • The pH, turbidity and concentration of PAH are constantly measured in accordance with MARPOL Annex VI resolution MEPC.184 (59).

- • The clean exhaust gases exit the scrubber, removed from sulphur and particulates, through a demister.

HK +852 9026 6074

HK +852 9026 6074